Demo Video:

Quick Overview

NX Laminate

Composites (NXLC) allows you to easily define laminates, assign them to 2D or

3D meshes of complex geometries, and post-process composite failure metrics.

For simple parts like test coupons, creating a FEM is not required, as NXLC allows

you to verify the ability of your laminate to withstand the following loading

conditions:

- Membrane forces

- Bending moments

- Transverse shear forces

- Temperature loads

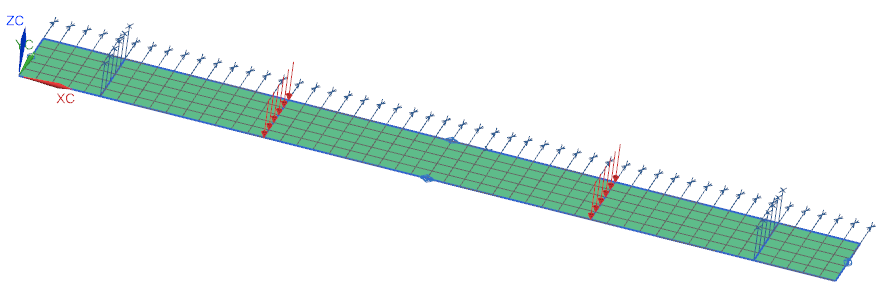

In this example we

will determine the loads required to produce first-ply failure in a 4 point

bending test coupon as per ASTM D7264. We will compare the NXLC results with

those of a shell element FEM with appropriate boundary conditions.

Laminated strip under four-point bending

Figure 1:

Laminate strip under three-point bending

A cross-ply laminate with [0/90/0/90/0/90/0]

layup is specified with the center ply being four times as thick as the others.

With such a lay-up, the bending moment is reacted more uniformly across the

section. A model, with appropriate boundary conditions, is used and predictions

are obtained using laminated shell elements.

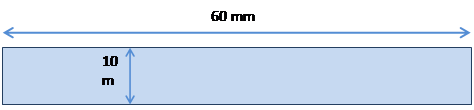

Figure 2: A laminate test specimen under four

point bending

The initial guess at the failure

bending moment is 1250 Nmm. The applied moment per unit length is 1250 N.mm/10mm

= 125 N

The applied load P = -4M/L = -(4*1250Nmm)/50mm= -100 N.

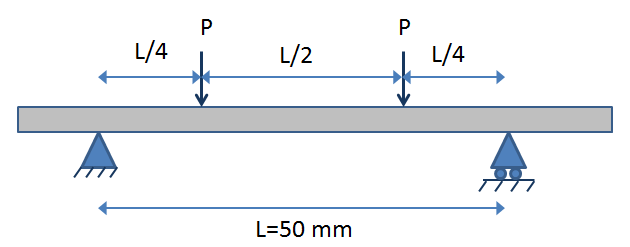

1.

Determine failure load Using NXLC

Create a new empty

FEM, by clicking NEW command.

Figure 3:

Create a new FEM

First, we define

the material properties to be used in the laminate definition.

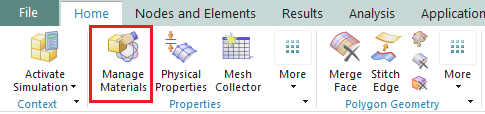

Go to Home tab and

under the Properties group click on Manage

Materials.

Figure 4:

Manage Materials

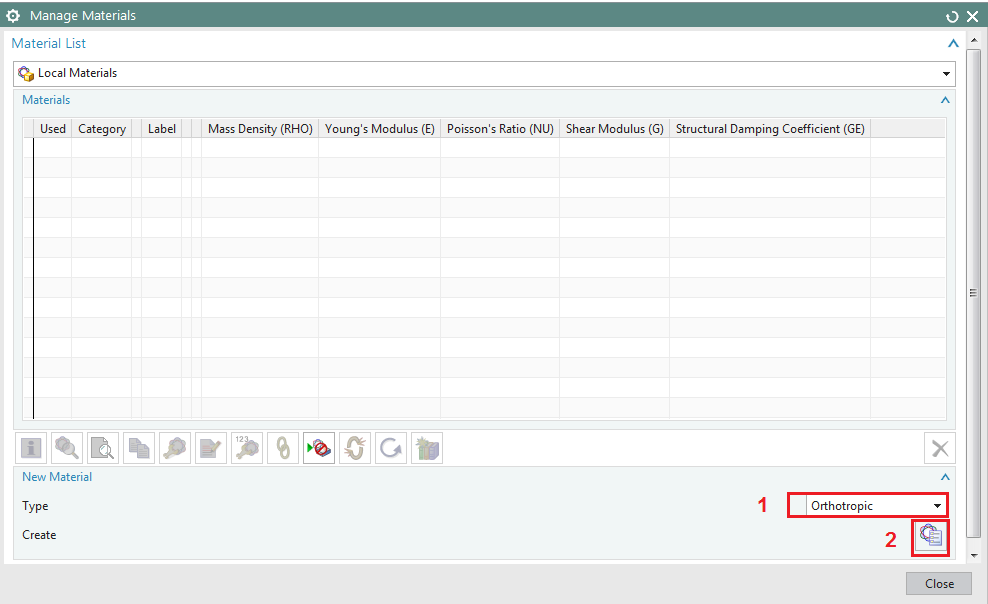

In the Manage

Materials dialog, set the type to Orthotropic

and click on Create.

Figure 5:

Define a new orthotropic material

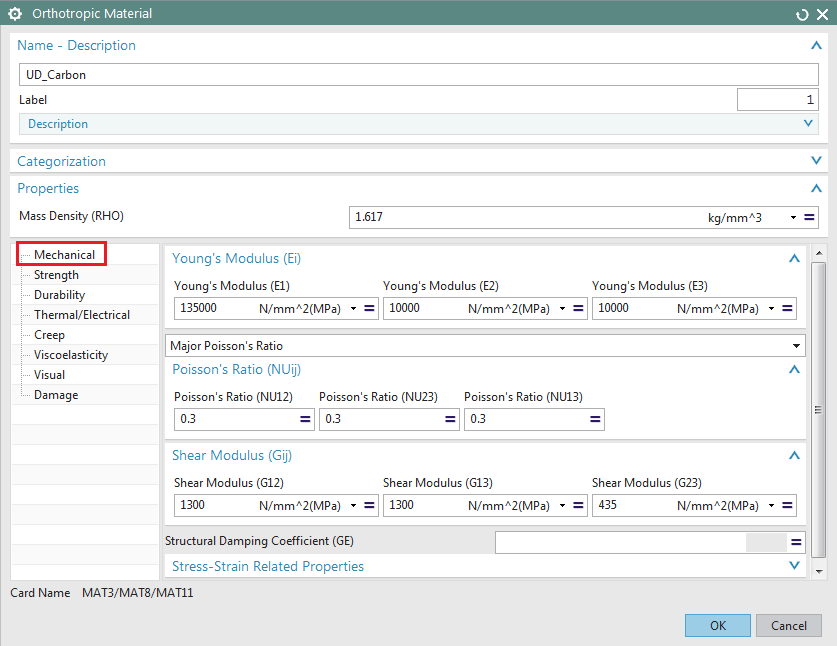

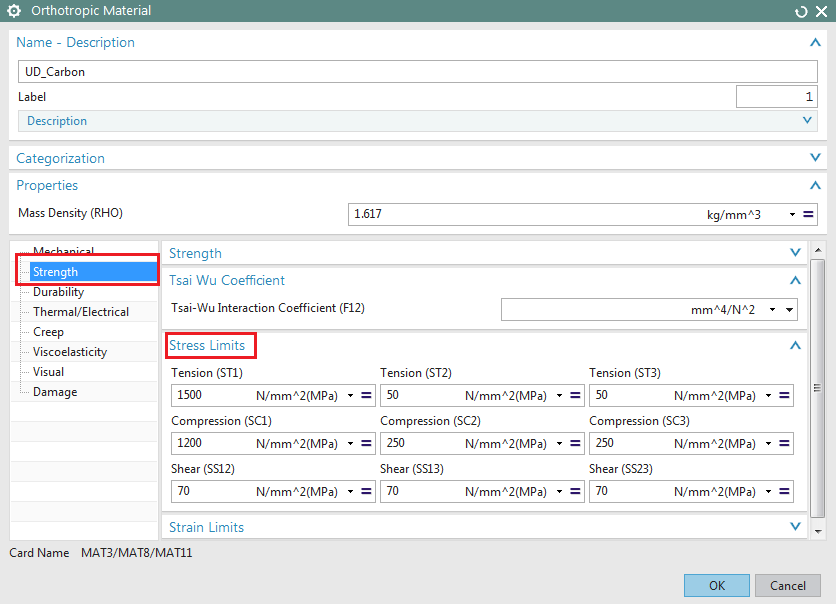

Then define mechanical and strength properties as shown in Figure 6

and Figure 7.

Figure 6: Define material mechanical

peroperties

Figure 7: Define material strength properties

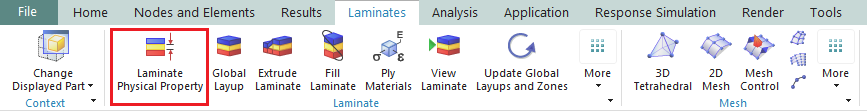

To define the

laminate, go to NX’s Laminates tab

and click the Laminate Physical Property

button.

Figure 8: Create a laminate physical property

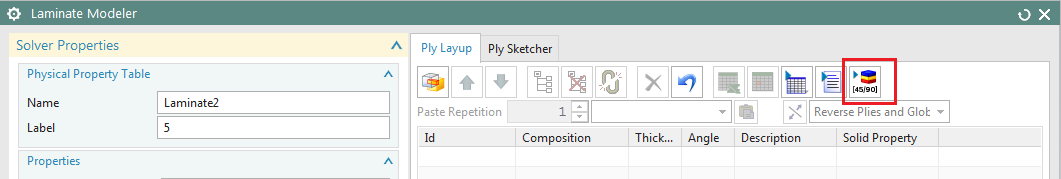

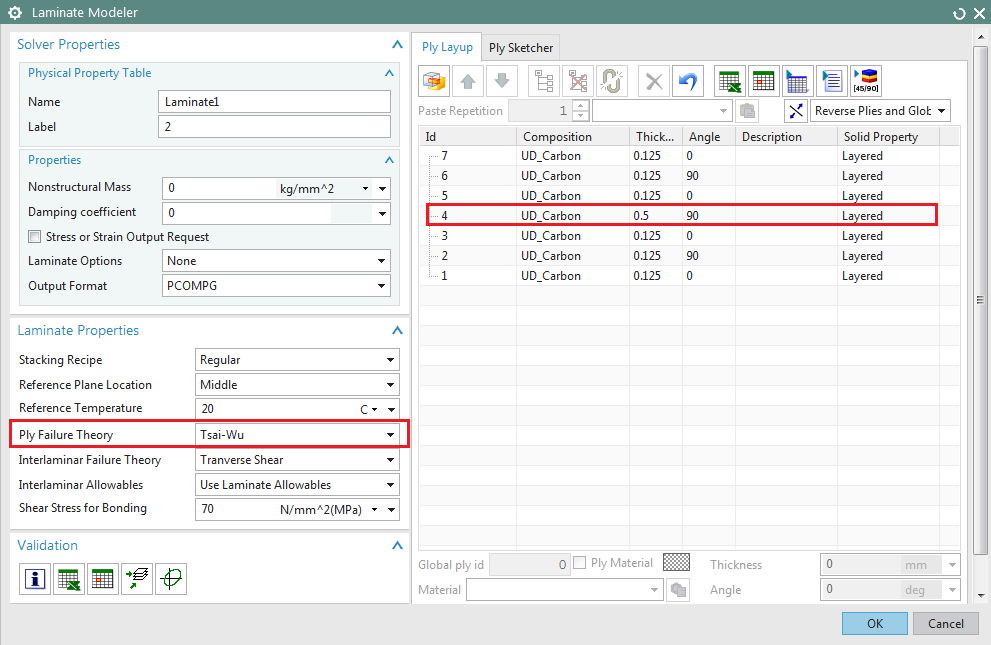

In the laminate

modeler, select Import Layup Using

Shorthand Format button to quickly define the layup.

Figure 9:

Import Layup Using Shorthand Format button

Figure 10:

Shorthand format to define a layup

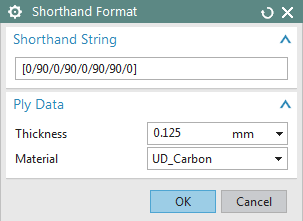

In the Laminate

Modeler dialog, set the output format to PCOMP, and the Ply Failure Theory to Tsai-Wu. Click OK to close the dialog.

Figure 11: A symmetric quasi-isotropic

laminate [0/90/0/90/0/90/0]

In the Laminate Modeler, under

the Validation group, click the Analyze Laminate Strength button.

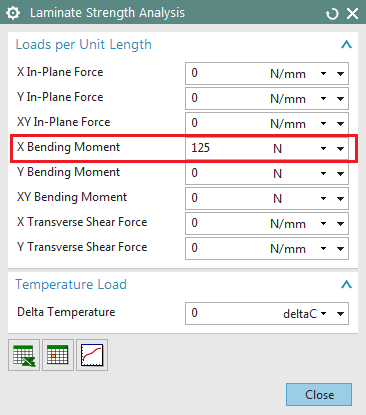

In the Laminate Strength Analysis dialog, enter the vaue of 125 N for X Bending

Moment per unit length and click on Export

Spreadsheet to generate the analysis results.

Figure 12:

Define applied load in Laminate strength Analysis dialog

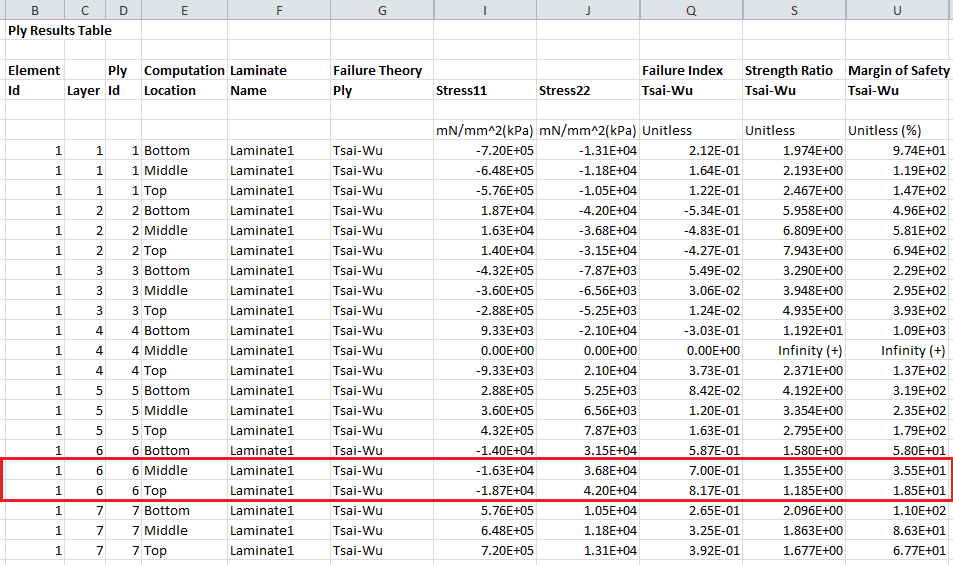

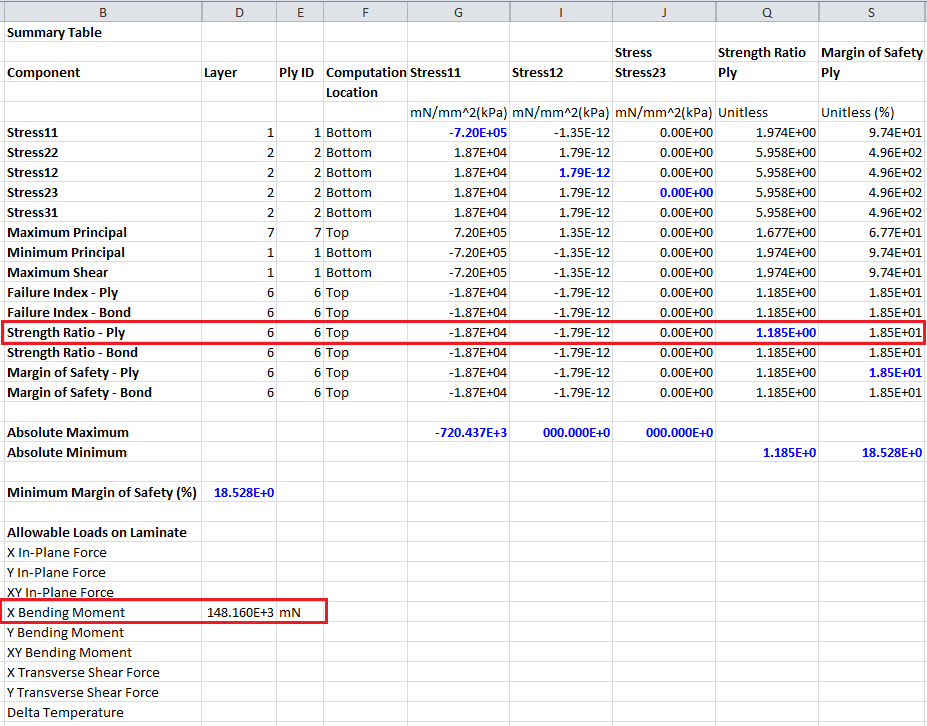

In Laminate 1 spreadsheet, navigate to Strength Analysis

worksheet to see the analysis results.

Figure 13:

A preview of a portion of the results generated by NX Laminate Composites.

Figure 14:

A preview of a portion of the result summary generated by NX Laminate

Composites.

The minimum strength ratio for

all plies is 1.185, which means the coupon will fail at a load of 1.185*1250Nmm=1481.25

Nmm, which is equal to a stress resultant of 1481.25Nmm/10mm=148.125N (shown in

the spreadsheet results under the Allowable

Loads on Laminate. Note that the slight difference is due to round off in

spreadsheet).

Keep your FEM open in NX.

2.

Determine

failure load using FEM

2.1.

Create the Coupon Geometry

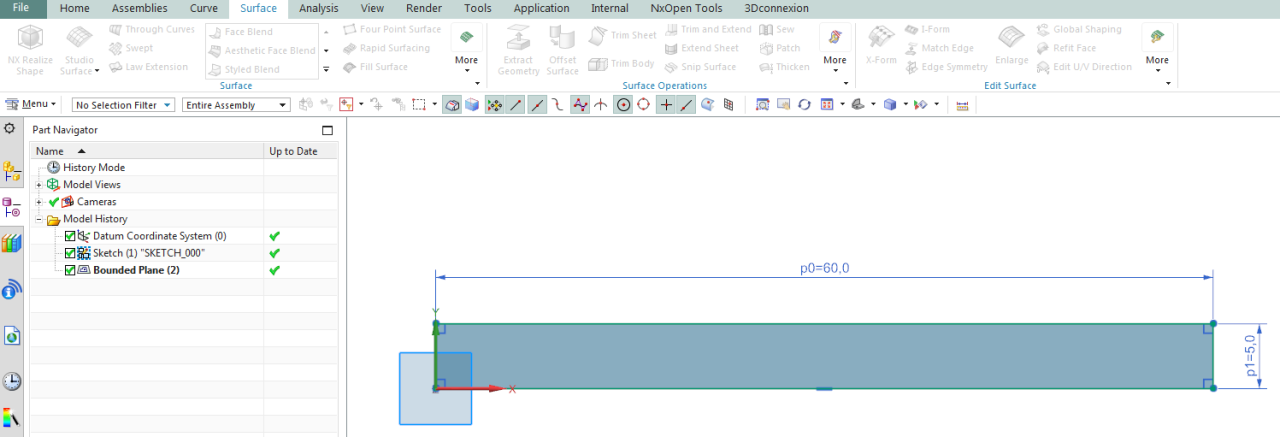

In the simulation

navigator, make your part file the work part, and create a rectangular face

with dimensions 60 mm x 5 mm, representing a half of the test specimen.

Figure 15:

Create geometry in NX

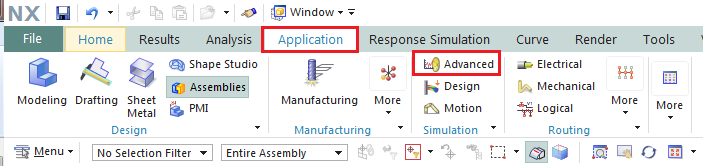

To create a FEM and

Sim, go to Application tab and click

the Advanced button.

Figure 16:

Create a FEM and Sim

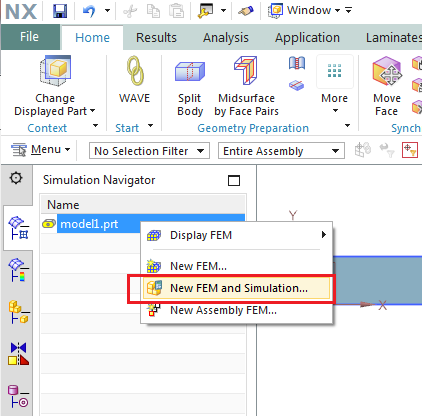

In the sim

navigator, right-click on the model and select New FEM and Simulation. Select the sheet body you just created and

click OK.

Figure 17:

Create a new FEM and Sim

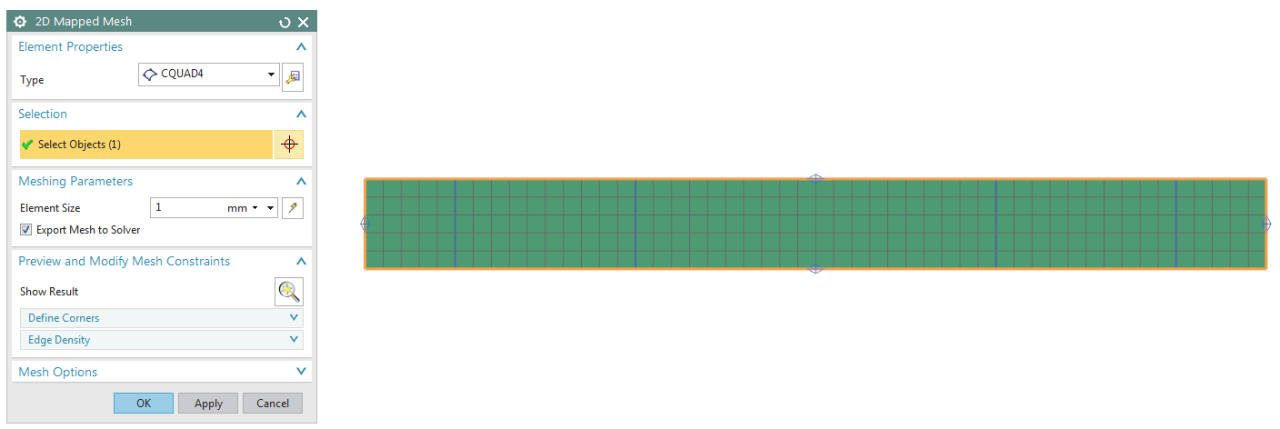

Then, make the FEM

work Part and create a 2d mapped mesh with 1 mm CQUAD4 element size.

Figure 18:

Meshing the geometry with 2D shell elements

2.2.

Assign

the Laminate Property to the Mesh

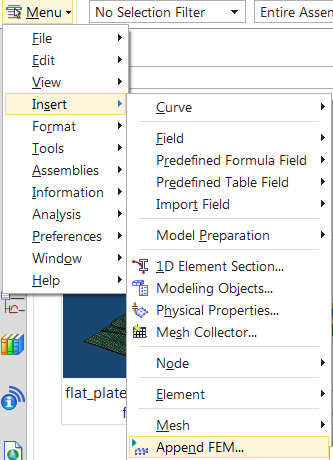

Import the physical property and the material you created in

your first FEM: From the Menu, Insert, Append FEM:

Figure 19:

Append FEM

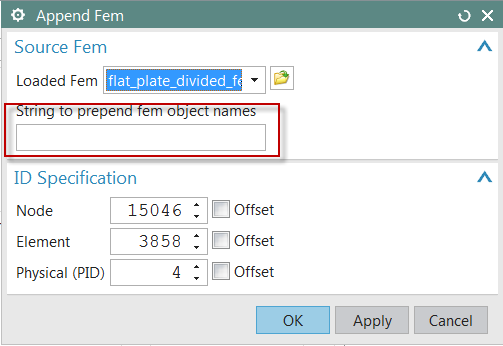

Your previous FEM name should appear in the Loaded Fem list. Remove the string in

the String to prepend fem object names

box, so that it is blank:

Figure 20:

Append FEM

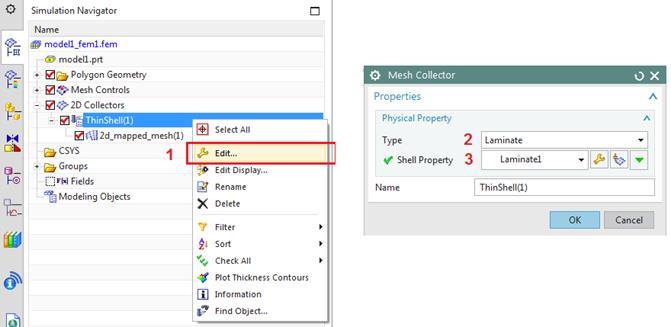

Then, in the sim navigator, right-click on the mesh

collector and select Edit. Then, in

the Mesh Collector dialog, set the Type to Laminate, and set the Shell Property to _Laminate 1 (the name

of the laminate layup that is defined in Figure 11)

Figure 21:

Assign laminate properties to the mesh

2.3.

Create Simulation

Create the Simulation file by

setting the solver to NX Nastran and the solution to SOL 101 Linear Statics – Subcase Constraints.

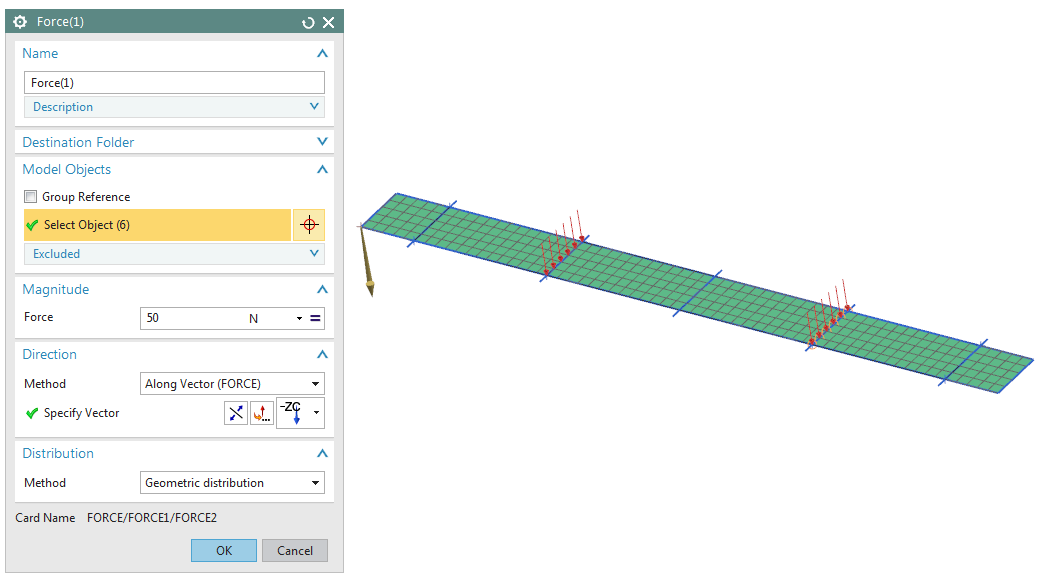

Make the sim work part. Note that

we modeled a quarter of the specimen: Therefore, the applied load in FEM will

be 100N/2=50 N to each of the line loads (Figure 2).

In the sim navigator, right-click on the Loads node and then select New Load, Force.

Figure 22:

Apply load along Z-direction

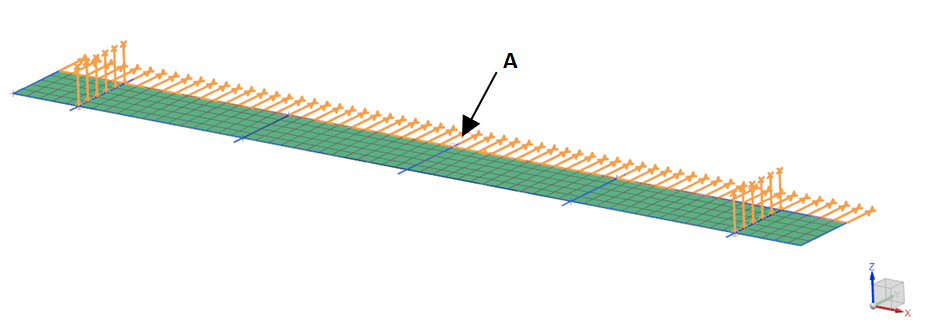

Apply the symmetry boundary

conditions to the top (DOF2=0) of the model. Then, fix DOF3=0 along the support

lines (Figure

2).

To prevent rigid body motion, it is needed to fix the center of the laminate

strip (Point A) along X-axis (DOF1=0).

Figure 23:

Apply symmetry boundary conditions

The model can now be solved.

2.4.

Post-Processing

In the Post Processing Navigator, the results are reported

for each ply separately. Therefore, we use NX

Advanced Post Report to extract the minimum strength ratio for all the

plies.

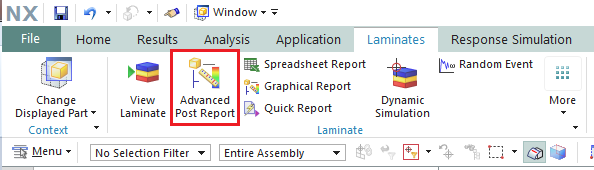

Go to the laminate Tab, and click Advanced Post Report. In the Laminate Post Report dialog, select

the solution name and click OK.

Figure 24:

Advanced Post Report

Figure 25:

Laminate Post Report Input selection

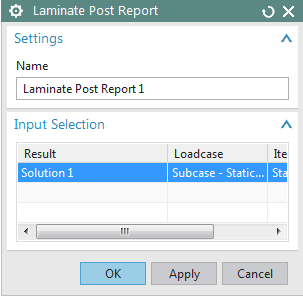

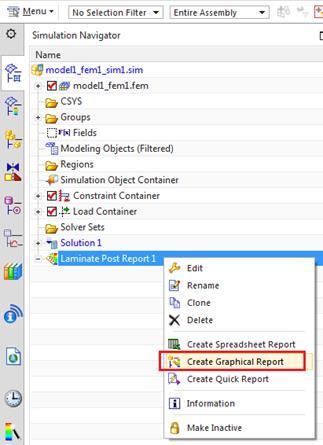

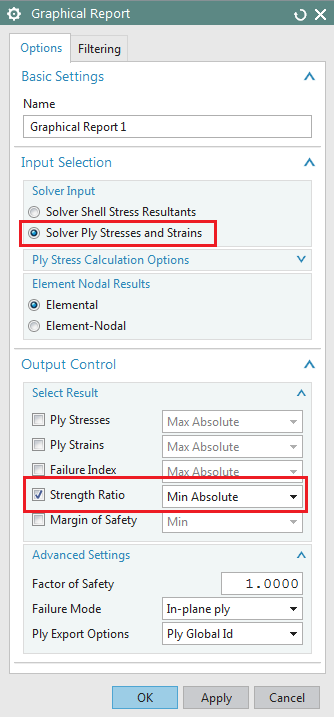

In the sim navigator, right-click on the Laminate Post Report 1 node and select Create Graphical Report.

Figure 26:

Create a graphical report

In the Graphical Report dialog, under the Solver Input

group, set the solver input to Solver

Ply Stresses and Strains. Then, under the output control group, check the Strength Ratio and set the filter to

Min Absolute, and click OK.

Figure 27:

Graphical Report dialog

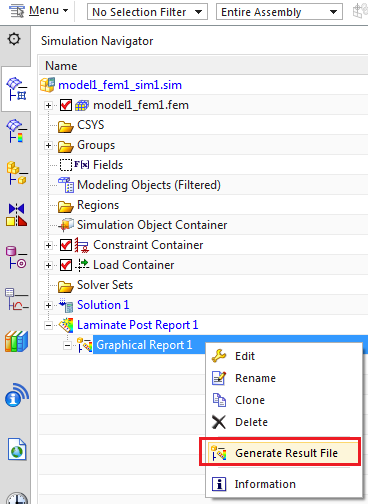

In the sim navigator, right-click on the Graphical Report 1

and select Generate Result File.

Figure 28:

Generate graphical post result

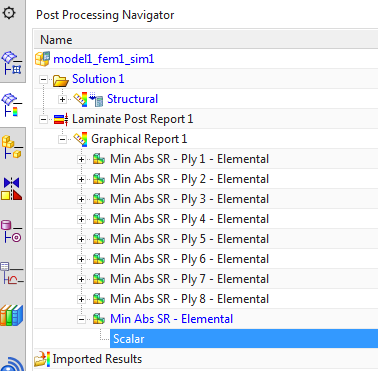

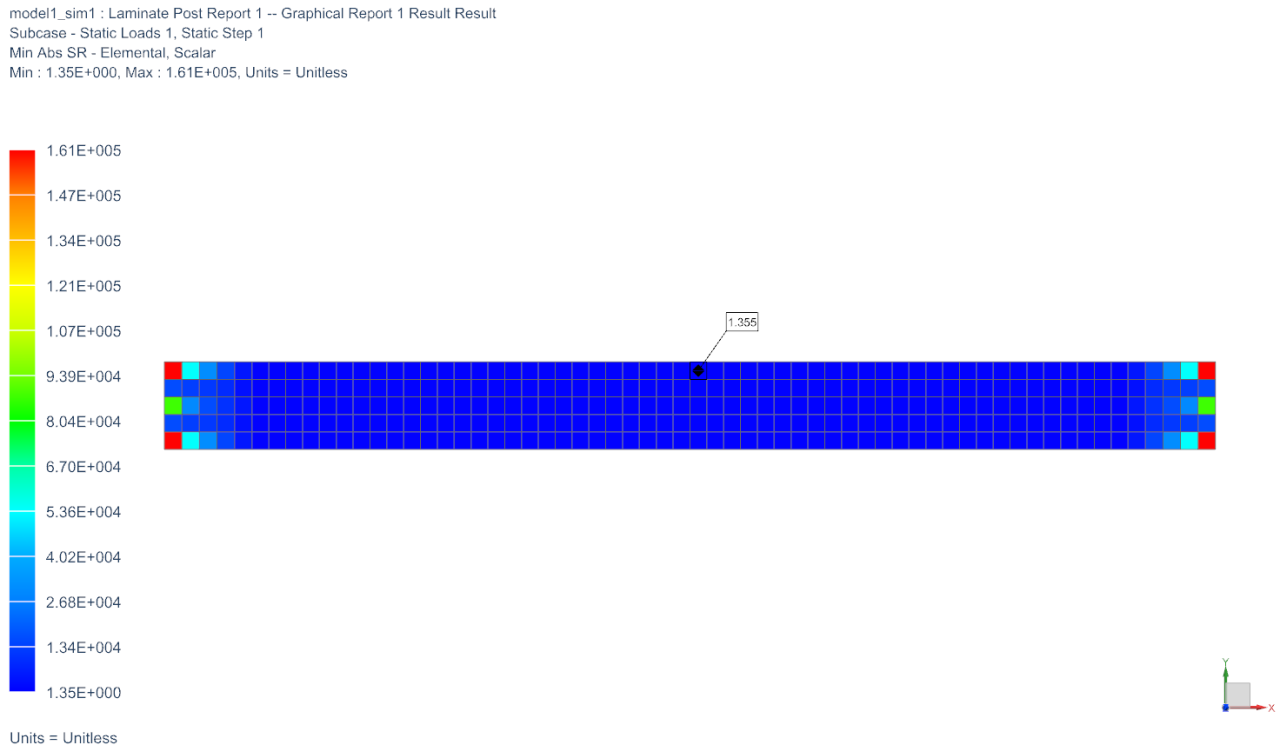

Switch to Post Processing navigator and expand Laminate Post

Report, and select Min Abs SR – Elementa.

Figure 29:

Min. strength ratio for all the plies

Figure 30:

Min. strength ratio for all the plies

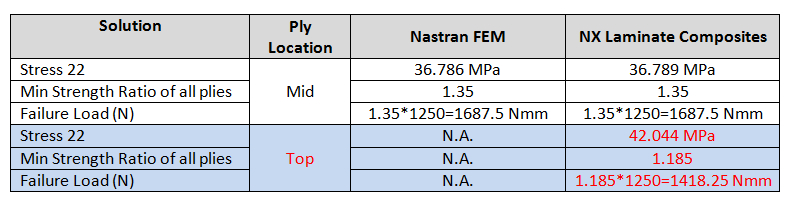

Table 1 compares some results obtained using the Nastran FEM

and with NXLC alone.

Table 1:

Compare FEM results to NX Laminate Composite results

NXNASTRAN only outputs the

mid-ply results for shell elements. From Table 1, it can be seen that when the

bending loads are dominant, relying on the shell element mid-ply results is not

conservative. NX Advanced Post Report

is capable of calculating and extracting the ply results at Top and Bottom of

the plies in order to achieve more accurate predictions. It also can be

concluded that the effort required creating the geometry, 2D mesh, solve and

post-process the results, was not necessary.