Quick Overview

Simcenter Laminate Composites (LC) allows you to optimize

the fundamental properties of a laminate coupon- for example, increasing its

modulus in the X direction, minimizing its mass or its thermal expansion- by

modifying ply angles, ply thickness, ply materials or by removing plies.

Core content

The optimization works on a

single laminate physical property and involves three components: design

variables, design constraints, and design objectives. The property does not

have to be assigned to a collector.

Design variables

LC supports the

following types of design variables for the plies of a laminate property:

- Ply thickness

- Ply angle

- Material assigned to the ply

- Ply existence, ie whether or not a ply can be

removed from the laminate

Ply thickness and ply angle

design variables can be either discrete or continuous. Ply materials and ply

existence are inherently discrete design variables.

Design Constraints

LC

supports the

following types of design constraints on a laminate:

- The total mass of the laminate

- The buckling factor for a plate of a given

coupon size - The ply failure index

- The natural frequency for a plate of a given

coupon size - The ply contiguity

- The equivalent laminate X and Y Young’s modulus

- The equivalent laminate shear modulus

- The equivalent laminate Poisson’s ratio

- The equivalent laminate X, Y, and XY thermal

expansion coefficients

Design objective

LC

supports the following design objectives:

- The total mass of the laminate

- The buckling factor

- The equivalent laminate X and Y Young’s modulus

- The equivalent laminate shear modulus

- The equivalent laminate Poisson’s ratio

- The equivalent laminate X, Y, and XY thermal

expansion coefficients

Steps

In this example, we are going to

use

LC

to minimize the mass of a deployed solar array with constraints on the

minimum natural frequency and equivalent longitudinal stiffness of each individual

solar array panel. The design variables are the ply thickness, ply angles, and

ply existence.

LC

optimization is well suited for the flat, rectangular

geometry of the array panels, even if the assumed boundary conditions are not

fully representative of the actual design.

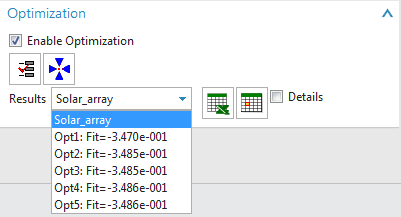

Figure 1

Spacecraft with deployed solar panels

Each solar array panel is initially

designed with a 12 mm thick aluminum honeycomb core, and symmetric 4-ply CFRP

face sheets [0/45/90/-45]s, in which each ply is 0.127 mm thick. The initial

design has a mass of 0.77 kg, an equivalent longitudinal stiffness of 8.79 GPa,

and a natural frequency of 76 Hz. The optimum design should have an equivalent

longitudinal stiffness similar to or greater than the initial design and with a

natural frequency of at least 20 Hz.

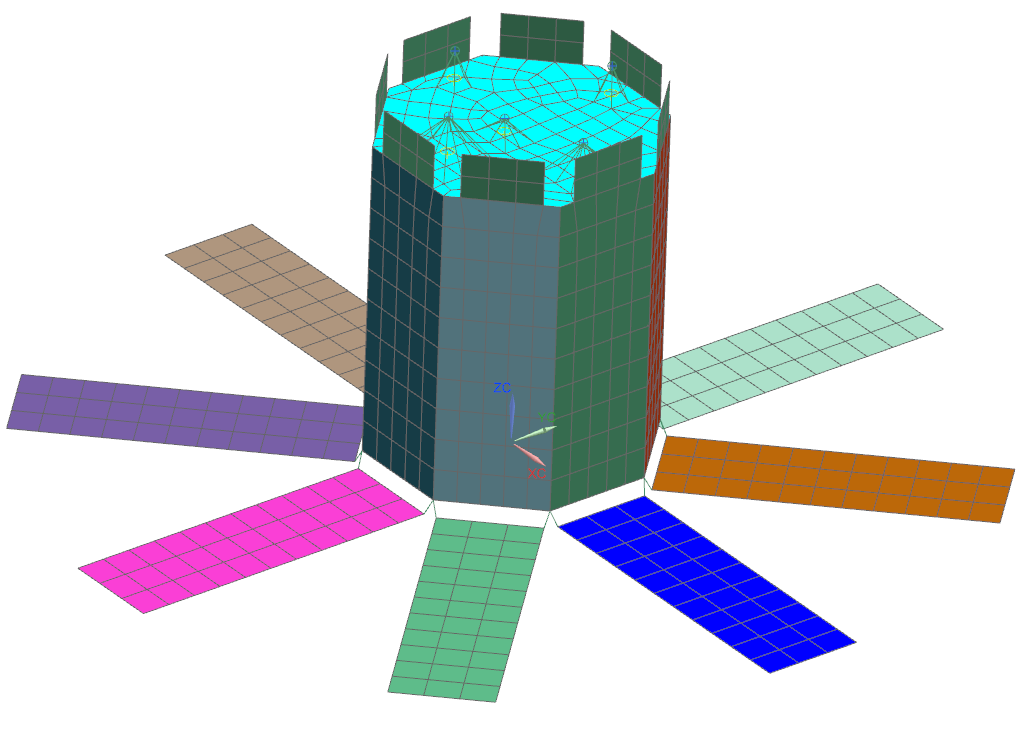

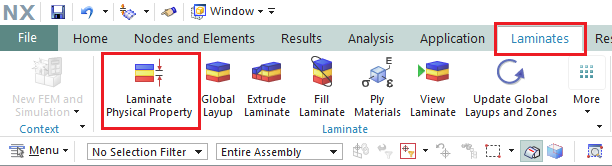

Define the laminate

To define the laminate

properties, In the Laminate tab click

Laminate Physical Property to define

the laminate layup.

Figure 2:

Define laminate layup

Figure 3: The initial design of solar array

laminate.

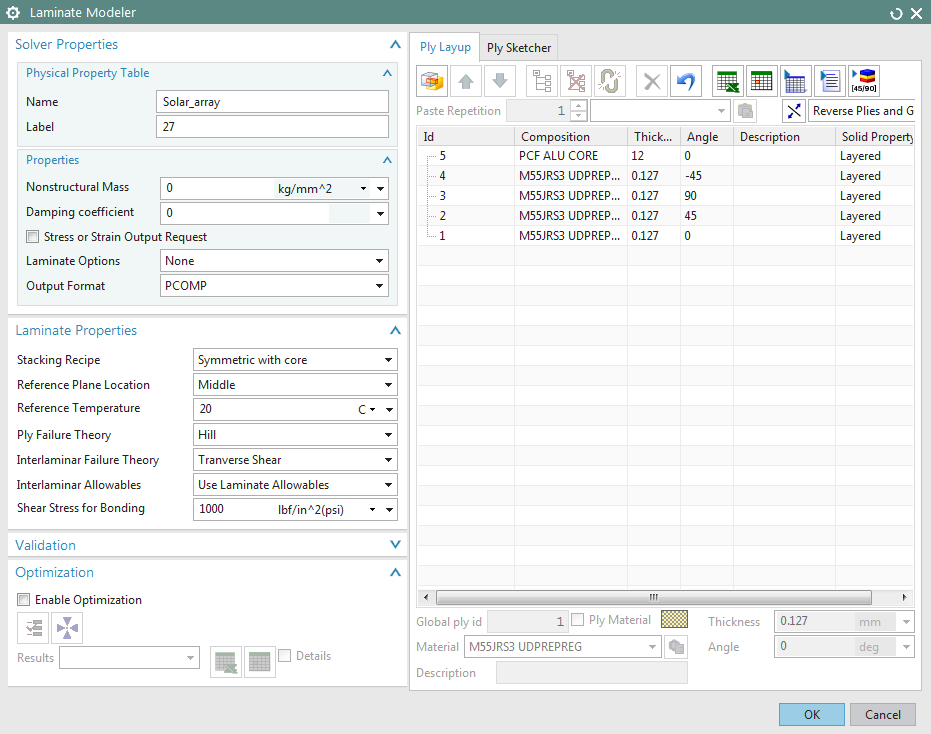

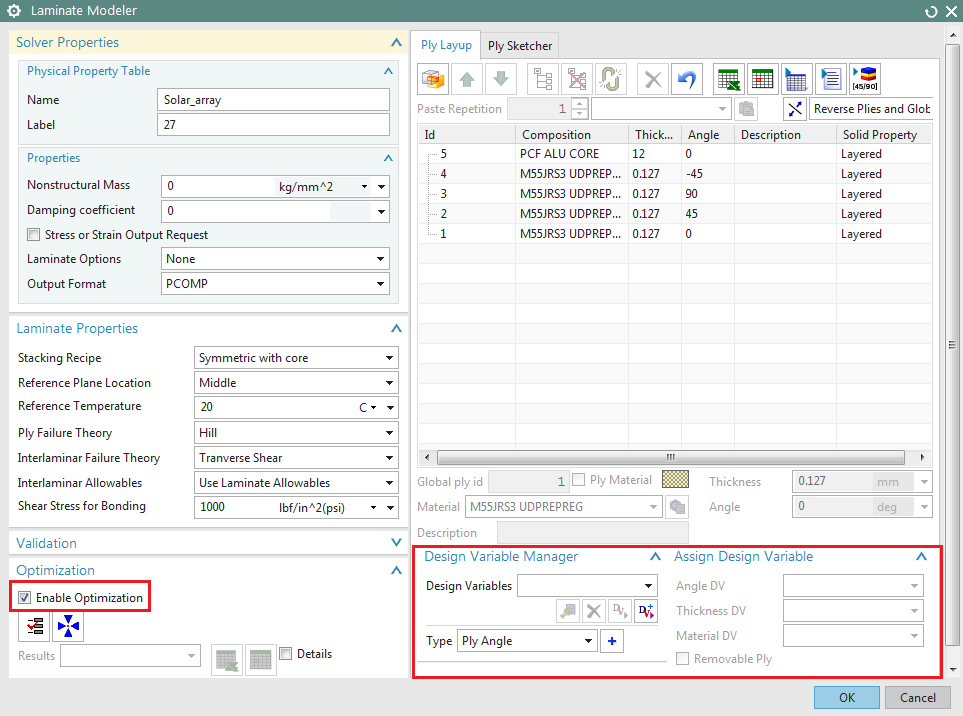

First, we need to define design

variables. In the Laminate Modeler dialog

under the Optimization group check Enable Optimization. As a result, a new

group is displayed under the ply layup definition table.

Figure 4:

Enable laminate optimization

Define design variables

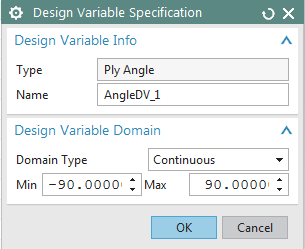

The design variables for this

example are ply angles, ply thickness, and ply existence. To define a design

variable for a ply angle, under the Design

Variable Manager group, set the Type

to Ply Angle and click

In the design variable specification dialog, specify a name for this

design variable, set the Domain Type

to Continuous, and set the Min and Max to -90 and +90, respectively. Click

OK.

Figure 5:

Define design variable for the angle of ply 1

Since the angle of each ply can

vary independently from the other plies, we need to repeat this process 4 times

to define ply angle design variables for each ply. Note that we do not need a

ply angle design variable for the core.

To define design variables for

ply thickness, under the Design Variable

Manager group, set the Type to

Ply Thickness and click

In the design variable specification dialog, specify a name for this

design variable, set the Domain Type

to Continuous, and set the Min and Max to 0.0508 mm and 0.254 mm,

respectively. Click OK.

Figure 6:

Define design variable for the thickness of ply 1

Similarly to the ply angle design

variables, we need to repeat this process 4 times to define ply thickness

design variables for each ply. For the core ply, create an additional ply

thickness design variable, where the limits of Min and Max are 8 mm and

25 mm, respectively.

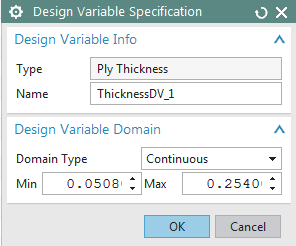

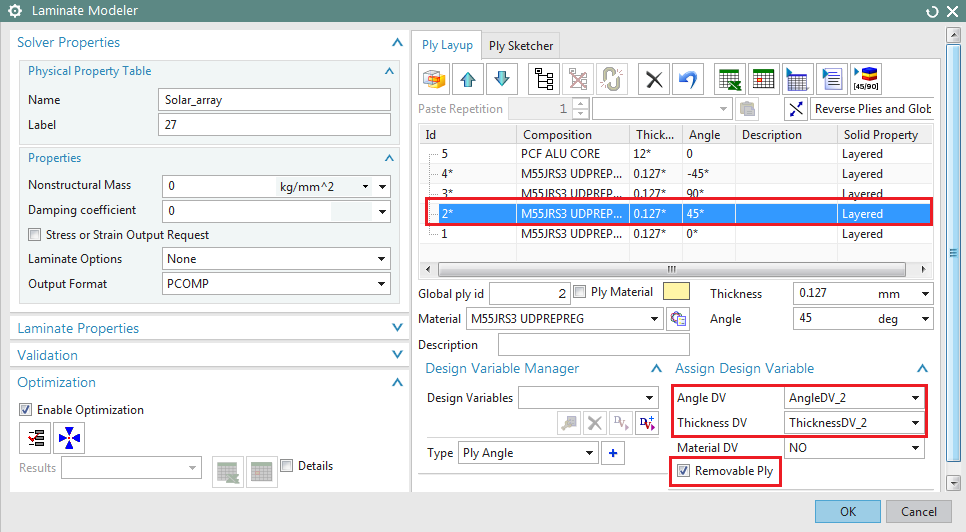

To assign design variables to a ply, in the Laminate Modeler dialog, select the ply

and under the Assign Design Variable

group, select the relevant ply angle design variable from the Angle DV drop down menu, which lists

all the defined ply angle design variables. Similarly, to assign a ply

thickness design variable use the Thickness

DV drop down menu, which lists all the defined ply thickness design

variables. Repeat the above process and assign the relevant design variables to

all the plies, including the core ply.

We want to keep the outer ply for

the final design, but the rest of the plies can be removed by the optimization

algorithm. To identify plies 2, 3, and 4 as removable, select them and check Removable Ply.

Figure 7: Assign design variables to a ply

Note that when a design variable is assigned to a ply, an asterisk

appears in the relevant column of that ply. For example, in Figure 7,

it can be seen that an asterisk is added beside the thickness and ply angles

for ply 1. Also for plies 2 to 4, there is an asterisk beside the ply id,

indicating these plies are removable.

Define objectives and

constraints

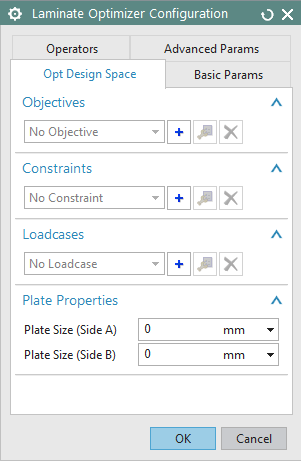

Under the Optimization

group, click

to open the Laminate Optimizer dialog.

Figure 8:

Laminate Optimizer Configuration dialog

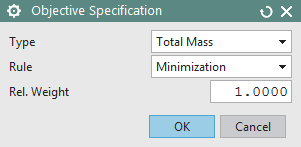

In the Laminate

Optimizer Configuration dialog, under the Opt Design Space tab, and under the Objectives group, click

to define the objectives. In the

Objective Specification dialog, set

the Type to Total Mass and set the Rule to Minimization, and click OK.

Figure 9:

define design objective

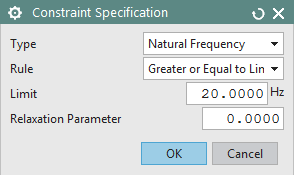

To define the constraint, in the Laminate Optimizer Configuration dialog, under the Opt Design Space tab, and under the Constraints group, click

In the Constraint Specification dialog, set the Type to Natural Frequency, and set the Rule to Greater or Equal to Limit. In the Limit box enter 20 Hz and click OK.

Figure 10:

Define design constraint on minimum natural frequency

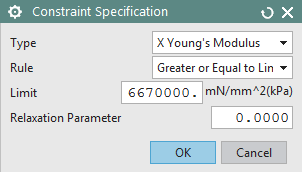

Repeat the process above and create a new constraint that

the minimum Young’s Modulus along X direction should be greater than 6.67 GPa

as shown in Figure 11.

Figure 11: Define design constraint on minimum

Young’s Modulus

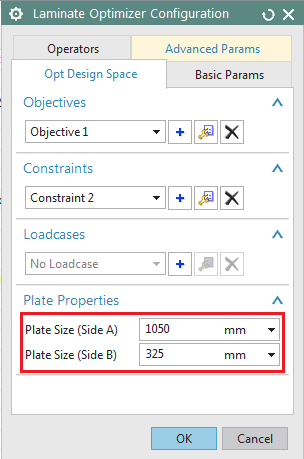

Then, under the Plate

Properties group, enter the plate size as 1050 mm for Side A and 325 mm for

Side B. Click Ok.

Figure 12:

Plate properties

Note: The

optimization in

LC

has two optimization algorithms: Standard and Hybrid genetic

algorithm. The parameters for the optimization algorithms can be tuned under

the Operators, Basic Params, and Advanced

Params Tabs. In this Tips and Tricks, we will use the default settings.

Launch the optimization process

In the Laminate modeler dialog, under the Optimization group, click

to launch the optimization

process. To see the best five optimum candidates and a summary of the

optimization results click

which exports the optimization results to a

spreadsheet. You can also check the detail

box, to have the layup and laminate properties for each of those five optimum

candidates.

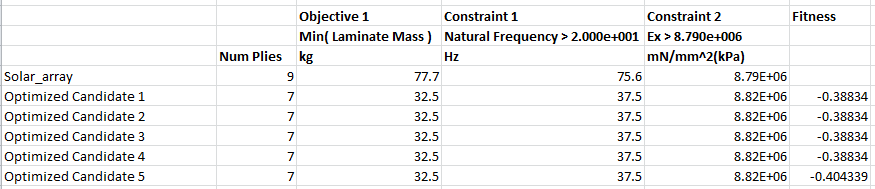

A summary of the optimization results is shown in Figure 13.

It can be seen that optimization algorithm removed 2 plies, reduced the mass by

about 58% while satisfying both constraints.

Figure 13: Summary of the optimization results

Finally, using the Results

drop-down menu, you can choose one of the candidate optimum designs and the

laminate definition is automatically updated to the layup of the selected optimum

design (Figure 14).