What Is Multi Plate Clutch?

Multi plate clutch is one of the main devices in transmission system and type of clutch, which transmits the power from engine to the driving wheels. Generally, Transmission system consists of clutch, gearbox, propeller shaft, universal joints, differential wheels, rear drive and tyres. Gearbox or transmission is used to obtain the change in speed and power; the clutch is employed for engineering and disengaging of gearbox with engine.

- Multi plate clutch is the most useful clutch in power transmitting among all the other types of clutch.

- The operating of multi plate clutch depends on the friction.

- A Multi plate clutch consists of more than one and more friction plates, three friction rings with friction linings.

The principle of multi plate is similar to that of single plate clutch. Friction plates are mounted over the clutch shaft through a spline arrangement. Thus the working of clutch is accomplished

Also Read

Purpose of A Clutch

- A clutch is a mechanical device used in transmission system of a vehicle to engage and disengage the engine.

- It allows the engagement and disengagement of a gear when the vehicle is at rest as well as in running condition.

- It transmits the power developed by the engine to the road wheels, without producing any vibration effects on the transmission system.

- It enables the changing of gear, which the vehicle is running to attain variable speeds.

Working Principle of Multi Plate Clutch

The operating principle of clutch depends on friction. It can be explained by considering two shafts and two discs. Clutch is divided in 3 main components members as follows.

- Driving members – This include flywheel, which is fixed to a cover, carrying pressure plate, pressure spring and releasing levers.

- Driven members – This include clutch plate, clutch shaft, etc. the clutch shaft rotates when the clutch plate is held in between the flywheel and pressure plate.

- Operating members – These include foot pedal linkages and bearing.

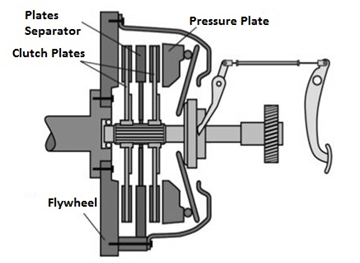

Main Parts of Multi Plate Clutch

The main parts of Multi Plate Clutch

- Clutch plate

- Clutch facing

- Pressure plate

- Springs

- Bearings

- Release levers

- Cover

Clutch plate – clutch plate is also known as friction plate or clutch disc and comprises of steel plate, friction facing and a central splined hub. The friction facings are attached to the steel plate with the help of rivets.

Clutch facing – It is one of the essential properties in the Multi Plate Clutch. It consists have good wearing properties and have less lining material. It possess sufficient binding characteristics too.

Pressure plates – it is made rigid to resist the pressure of the clutch springs. It is made of high tensile grey cast iron material. It should have particular mass and thermal conductivity, in order to absorb the heat generated during engagement of the clutch.

Springs – normal springs are made of oil tempered spring steel wire; whereas to prevent heat. To prevent the heat conduction between pressure plates and springs insulating washers are provided. The spring stiffness should be maximum so that, after wear of the clutch facing required amount of spring force in left after extension.

Bearings – it transfer the pedal force from stationary linkage to rotating clutch

Release levers – generally release levers are placed around the pressure plate.

Cover – it is made of steel, fixed to flywheel and covers the pressure plate assembly. It has holes to dissipate the heat produced.

Construction of Multi Plate Clutch

- A multi plate clutch consists of more than one friction plate. So, it has two friction plates and three friction rings with friction lining splines, are provided on outer circumference of friction rings, which are positioned in the clutch cover, then attached to the flywheel.

- The friction rings are free to slide over the splines of clutch cover the position of the friction plate in such that, one is placed in between the pressure plate, and the other is in between the flywheel and the pressure plate.

Working of Multi Plate Clutch

- When the clutch is in engaged position, pressure plate keeps friction rings pressure upon friction plates. Due to this the friction plates start rotating and thus rotating driven shaft.

- By pressing the clutch pedal, the thrust bearing moves towards left. Thereby, the pressure plate to move away from the flywheel and this action compresses the clutch springs, which in turn leads to pressure removal from the clutch plate.

- This enables the clutch plate to move back from the flywheel and thus the driver shaft becomes stationary. By releasing the clutch pedal, the thrust bearing moves back and allow the springs to extend, which pushes the clutch plate towards the flywheel.

- This engages the flywheel and the clutch plate, which result in rotation of the driven shaft.

Difference Between Single Plate And Multi Plate Clutch

| Single Plate Clutch | Multi Plate Clutch |

| 1. Single plate clutch consist only one clutch plate. | 1. The multi plate clutch consist two or more than two plates. |

| 2. The torque transmission capacity is less. | 2. The torque transmission capacity is more or high. |

| 3. This type of clutch generates less heat. It may require any cooling medium. | 3. This clutch generators more heat due to the large friction surface. It may need cooling medium. |

| 4. The coefficient of friction is high | 4. The coefficient of friction is low. |

| 5. The single plate clutch is used where large or more load is carrying. Ex. Trucks or Cars | 5. The multi plate clutches are used where compact is desirable. Ex. Motorcycle or Scooters. |

Advantages of Multi Plate Clutch

The advantages of Multi Plate Clutch are

- The number of contact surfaces are more in multi plate clutch.

- For same clutch size, the torque transmitting capacity of multi plate clutch is high.

- Design of multi plate clutch is compact.

Applications of Multi Plate Clutch

The applications of Multi Plate Clutch are

- Agricultural tractors use multi plate clutch devices in which a continuous drive is required at the power take off.

- Used in earth moving vehicles.

- Used in heavy duty vehicles such as army force armed vehicles.

- Used in motors bikes commonly, but is in smaller size.