How to take control of arc flash and prevent electric shock.

By Terry Becker, Contributor

I thought I would provide a brief article highlighting some of the questions that I still get asked often, or new questions that come up after providing electrical safety consulting, during electrical safety audits and when delivering arc flash and electric shock training for the last 17 years.

We have a long way to go, and it is important we all manage misinformation, myths, disinformation, assumptions, speculation and hearsay related specifically to abnormal arcing fault and arc flash. It is in the best interests of the Qualified Person, and the employer that fear-based, and anxiety-based marketing and messaging are not applied. This tactic may actually lead to increasing the likelihood that a Qualified Person is exposed to the electrical hazards we are trying to eliminate exposure to by creating uncertainty and doubt, and preventing them from reducing the risk to as low as reasonably practicable. We need Qualified Persons to be confident, we need to manage human performance and the potential for human error.

A compliant Electrical Safety Program (ESP) can improve human performance by improving a worker’s ability to manage factors that may interfere with the effectiveness of risk controls, such as:

- Workplace Culture

- Mental Health Issues and Concerns

- Distractions

- Information Overload

- Training and Competency

- Errors, Mistakes and Lapses

- Complacency

- Time Pressure

- Violations

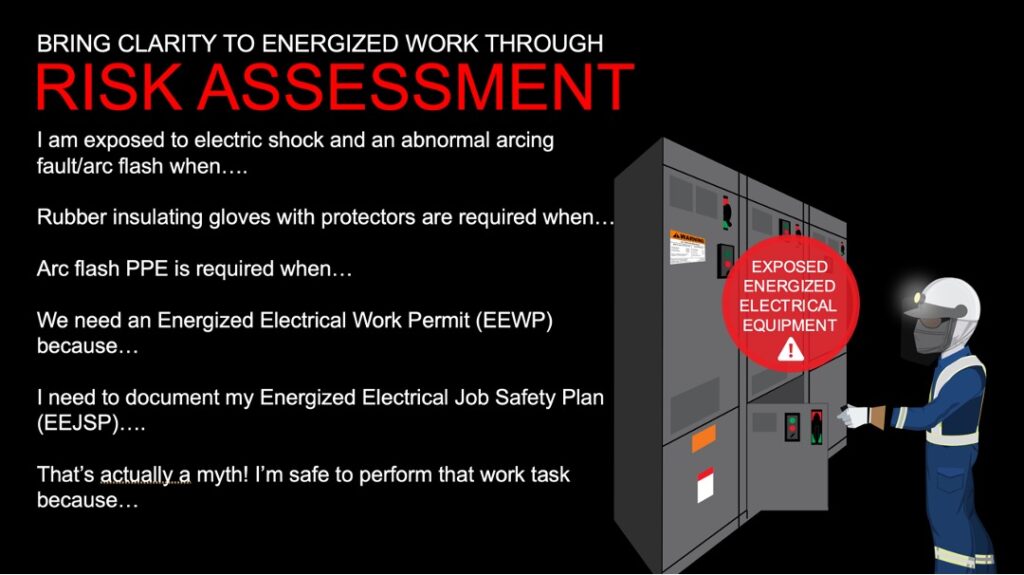

Graphic courtesy of TW Becker Electrical Safety Consulting, Inc.

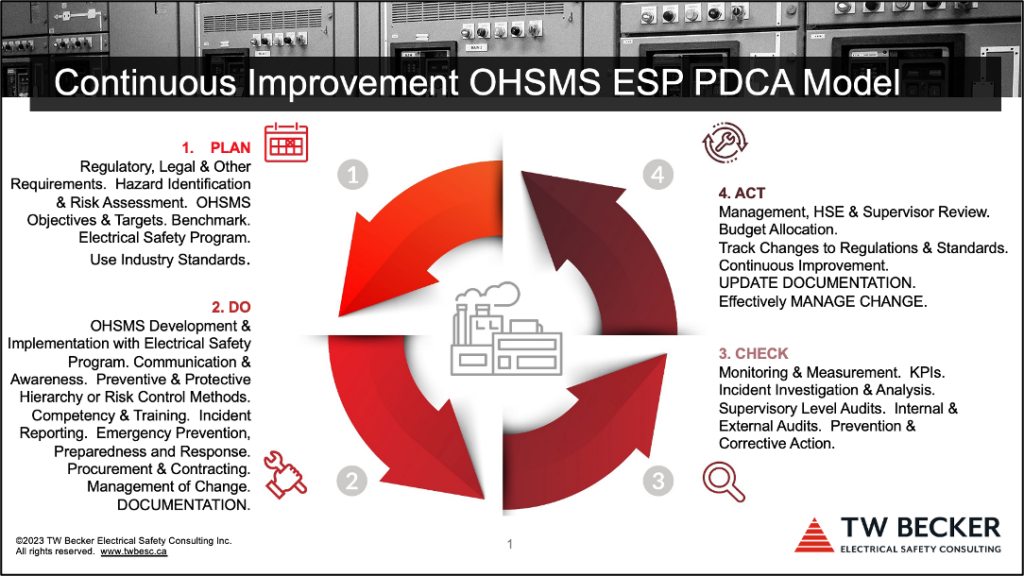

I have been applying a continuous improvement model, PLAN-DO-CHECK-ACT to electric safety for over 17 years. Sustainable and defendable due diligence is achieved by developing, implementing and auditing a compliant Electrical Safety Program.

Image courtesy of TW Becker Electrical Safety Consulting, Inc.

FREQUENTLY ASKED QUESTIONS

Here are some of the questions I have received and my answers. If you disagree, have other facts or substantiation I may not have, please send me an email, terry.becker@twbesc.ca.

Q: If I open the circuit breaker or disconnect switch, is it true that I do not need arc flash or electric shock PPE to then open the hinged door or remove the bolt on cover and go into the electrical equipment with my hands?

A: This of course is not true. Suitable arc flash and electric shock PPE are required to be worn until you have tested with an approved test instrument and verified the absence of voltage in the electrical equipment, and you have completed all related work tasks to establish an electrically safe work condition that will not expose you to an abnormal arcing fault, arc flash or electric shock from exposed conductors and circuit parts.

You can bring clarity to executing energized work tasks through risk assessment:

- I am exposed to electric shock and an abnormal arcing fault when …

- Rubber insulating gloves with protectors are required when …

- We need an Energized Electrical Work Permit (EEWP) because …

- I need to document my Energized Electrical Job Safety Plan (EEJSP) when …

- That’s actually a myth! I’m safe to perform that work task because …

Q: Do I need ‘special’ ear canal insert ear plugs? I heard a vendor has “arc-rated” ear canal insert ear plugs.

A: A lot of PPE is advertised/marketed as “arc-rated” when it actually is not. There is a vendor claiming they are providing arc-rated ear canal insert ear plugs when they are not arc-rated with an Arc Thermal Performance Value (ATPV). Any ear canal insert ear plug can be worn. If you are exposed to an arc flash and your ears are covered with arc-rated fabric from a balaclava or arc flash suit hood, the ear canal insert will not be directly exposed to incident energy. Plasma from an abnormal arcing fault doesn’t bend, it breaks around you. Also, I have not seen evidence from electrical incident statistics where arc flash PPE was worn that ear canal ear plugs melted.

Q: Will the plastic safety eyewear I need to wear underneath the arc-rated face shield or arc flash suit hood melt from the incident energy exposure to the arc-rated face shield or arc flash suit hood?

A: This was a new question. My response was not likely. The melting temperature of polycarbonate plastic is 295 Deg C. And, I have not seen evidence from electrical incident statistics where arc flash PPE was worn that plastic approved eyewear worn melted.

Image courtesy of TW Becker Electrical Safety Consulting, Inc.

Q: Do I need an Energized Electrical Work Permit (EEWP) issued to me to operate energized electrical equipment before I do any work on it?

A: The EEWP requirement always included four exemptions in NFPA 70E. I always recommended to clients that in the compliant Electrical Safety Program we include six additional specific energized electrical work tasks due to equipment design. The EEWP should not add bureaucracy to electrical equipment maintenance with no value. For example, the CEO, President, VP, etc. of the company should not be required to sign an EEWP for routine maintenance or isolation work tasks. The EEWP implementation is used for every justified repair or alteration work task, and should be managed at the field, operations level with the maintenance department. Applicable signatures are determined by the employer, but I have always recommended: requester, supervisor, manager and Qualified Person.

Q: Do I need full body arc flash PPE to go into and electrical room, be in front of electrical equipment and operate it, or to be there when it might automatically operate? I was told an abnormal arcing fault is very likely to occur.

A: This is misinformation and a lack of completing a risk assessment for your facility’s electrical equipment assets. Vendors would like you to believe this is true so you will buy arc flash PPE for all workers, or you will need to buy our expensive “Chicken Switch.”

We need to hold electrical equipment manufacturers accountable here as well. Did they sell us inherent unreliable, unsafe electrical equipment? If yes, why would be buy it? Was it not designed and manufactured to stringent standards that included exhaustive testing and that anticipated mean-time-between failures would be limited?

Q: If the incident energy level is 40.0 cal/cm2 we were advised that the ‘arc flash pressure’ will be ‘extremely high’ — thousands of pounds per square foot and will pulverize the Qualified Person. They told us, and the arc flash and shock equipment labels indicated “Dangerous, No PPE Exists.” It was in the electrical engineers’ report, they are subject matter experts, are they not?”

A: This unfortunately has not been true. There is not direct correlation between incident energy and “arc blast pressure.” Original research from Ralph Lee in the late 1980s when he was working for Dupont provides the theoretical formulas not only for incident energy and the arc flash boundary, but also his analysis of pressure which he determined directly correlated to abnormal arcing fault current. This information was published in his papers and also the IEEE Yellow Book, which is not the IEEE 3007 series. You will see his graphical representation of the distance from the abnormal arcing fault, the abnormal arcing fault current and the calculated “arc blast pressure” in pounds per square foot.

Additional new research presented at the 2024 IEEE Electrical Safety Workshop now indicates that we should reference the pressure as “pressure from an arcing fault.” This new research indicates the “pressure” is predominately generated by the abnormal arcing fault as an acoustical energy wave. This new research also indicated that copper when vaporized only expands 5000 times, not 67,000 times.

Q: I keep seeing a high volume of posts on LinkedIn from multiple sources with arc flash videos. Arc flashes must be occurring every day or multiple times a day in the United States?

A: Social media posts are another problem. This doesn’t help our overall mission related to electrical safety. It doesn’t help the Qualified Person or the ‘decision makers’ in a company. Most of the posts do not list any background information, no location, no date, nothing. Just hearsay, assumptions, and speculation and story or quotes that, “another person may have died, etc.”

Using a formal work task-based risk assessment procedure. an employer can prove that the likelihood of an abnormal arcing fault when energized electrical equipment operates or is operated is “unlikely.”

Q: When I ask the Qualified Persons, “do you know if maintenance mode switches and arc flash relays are programmed,” and they said no …

A: This is a significant problem. My experience is that this is a breakdown between capital projects, and operations and maintenance related to a new facility designed, constructed and commissioned.

The commissioning report from the maintenance and testing contractor needs to be issued to the electrical maintenance department and the Qualified Persons should be able to access the report to confirm the maintenance mode switches or arc flash relays have been programmed.

Additionally, the employer confirms that the programming has been completed and installs additional 8.5 X 11 signage with specific notification that these incident energy reduction engineering safety-by-design elements have been included in the power system design, and procedurally, the Qualified Person needs to follow the instructions listed. For example:

- When I ask the Qualified Persons when onsite providing ESP Roll Out Orientation Training, and we are reviewing and actually executing energized work tasks, “Do you know how to rack in or out this new Schneider MasterPact LV power circuit breaker?” And then the answer I receive is, “Isn’t it the same as the existing LV power circuit breaker we have in service?” How would you respond?

- Unfortunately, this is not true. There is a pro and a con to this. Advancements in electrical equipment technology are positive, but I am finding that we are over-engineering ‘safety by design’ features, and in this case, there are three interlocks required to be understood. I would respond by saying, “Do you know the three interlocks?”

Q: Is it true that if I am not an electrical engineer, I cannot use the arc flash PPE category method because it requires an engineering short circuit study to be completed?

A: This is a false statement. The NFPA 70E Arc Flash PPE Category Table Method was and is intended to be used directly by the Qualified Person without an electrical engineer providing any calculations.

For Table 130.7(C)(15)(a) Arc Flash PPE Categories for Alternating Current (ac) Systems for each row of electrical equipment, it lists a maximum available fault current value that needs to be confirmed. A simple short circuit calculation is all that is required, or a maximum available fault current look up table can be provided for the Qualified Person to reference related to the transformer kVA and %Z for the electrical equipment they will work on. As noted in the Informational Note 1, typical fault clearing times of overcurrent protective devices can be referenced.

There are actually many more questions I have been asked, and I am sure I will be asked many more in the future. I will endeavour to always answer them all with logic, reasonable interpretation, using facts NOT fiction, through the use of risk assessment to interpret and make decisions and instilling confidence with the Qualified Person. We need to take control of arc flash and ensure electric shock gets appropriate attention!

If you are interested in discussing the information presented in this article, or would like a specific topic presented in a future article, do not hesitate to contact me at terry.becker@twbesc.ca or 587-433-3777. ESW

Terry Becker, P.Eng., CESCP, IEEE Senior Member is a founding member and the First Past Vice-Chair of the CSA Z462 Workplace electrical safety Standard Technical Committee and currently a Voting Member and Clause 4.1 and Annexes Working Group Leader. Terry is also a founding member and Voting Member on the CSA Z463 Maintenance of electrical systems Standard and a Voting Member of the IEEE 1584 Guide for Performing for Arc-Flash Hazard Calculations. Terry is also a voting member of the CAN/ULC S801 Standard. Terry has presented at over 95 Conferences and Workshops on electrical safety in Canada, the USA, India, Australia and Italy. Terry is a Professional Engineer in the Provinces of BC, AB, ON and PEI. Terry is an Electrical Safety Specialist, Management Consultant, and can be reached at 1-587-433-3777 or by email terry.becker@twbesc.ca.