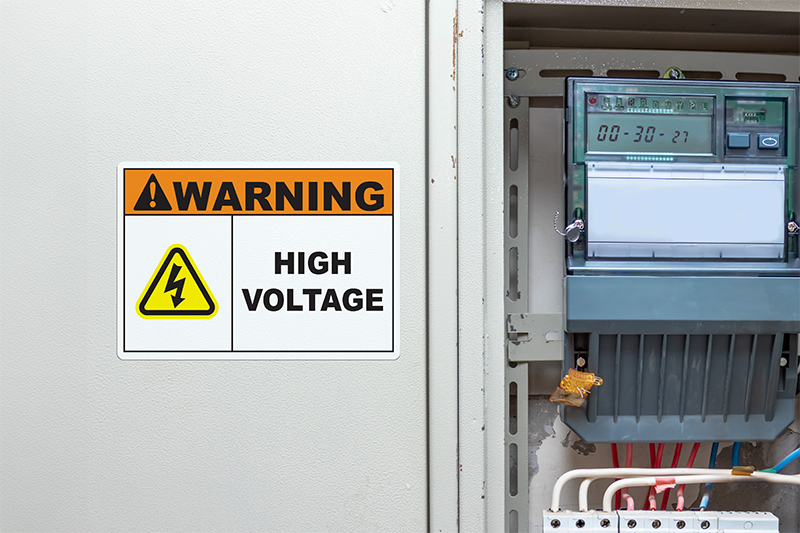

Several critical elements must be incorporated into the design and placement of electrical panel labels to effectively communicate risks. Image courtesy of Graphic Products

By: Henry Verdine, Contributor

Electrical panels are essential components of every facility’s infrastructure and serve as control points for electrical circuits. They also pose significant risks if improperly handled or maintained. The National Institutes of Health (NIH) found these shocking numbers related to electrical hazards:

- 400 high-voltage electrical injuries per year

- 30,000 non-fatal shock incidents per year

- 1,000 deaths per year

Maintaining electrical panel safety is a critical part of any workplace safety program, and one of the most effective ways to mitigate the risks is through clear, compliant visual communication. Labels play a critical role in warning workers about electrical hazards and providing vital information for safe operation.

This article explores how to enhance electrical panel safety by using proper labels, compliance with safety standards, and the specific visual communication elements that make labels effective in reducing risks.

The Dangers of Improperly Labeled Electrical Panels

Unlabeled or poorly labeled electrical panels present numerous dangers. Workers who lack the information to assess the risk of working near or on electrical panels are exposed to the potential of electrical shocks, burns, or even fatal electrocution. Many electrical panels look similar, so without clear labels, workers may mistakenly access or work on live equipment.

Key Elements of Effective Electrical Panel Labels

Accurately labeling electrical panels requires more than just affixing a generic warning label. Several critical elements must be incorporated into the design and placement of electrical panel labels to effectively communicate risks.

Color Coding

Color is one of the most basic but powerful elements of electrical safety labeling. OSHA and ANSI have defined color standards for safety signs, making it easier to quickly convey danger levels.

Red labels signify immediate danger, typically associated with high voltage or arc flash risks.

Yellow labels indicate caution, warning workers of potential hazards.

Green labels are often used for instructional labels, providing information on safe operation.

By maintaining consistent color schemes throughout a facility, workers can immediately understand the type of hazard they face.

Text Clarity

Text on electrical panel labels must be clear, concise, and easy to read. Large, bold fonts are essential, especially in environments where visibility might be compromised, such as in areas with dim lighting or outdoor facilities.

A label reading “Danger: High Voltage – Keep Away” in large, bold letters can prevent workers from unintentionally opening a panel containing live electrical parts. In contrast, labels with small text or technical jargon may confuse workers or go unnoticed.

Pictograms and Symbols

Pictograms provide a universal form of communication that can be understood regardless of language. ANSI Z535 defines standardized symbols for electrical hazards, which should be included on labels.

Symbols like the lightning bolt for electrical shock hazard or the arc flash symbol for high- energy electrical discharge are instantly recognizable and help to reinforce the written message.

Location and Durability

Labels must be placed in prominent, easy-to-see locations on electrical panels. The label must be positioned near the hazard area, whether it’s on the door of a panel or beside a key operational switch.

The durability of the label is another consideration. Electrical panels are often exposed to extreme temperatures, moisture, chemicals, or direct sunlight. For this reason, labels should be made from durable, weather-resistant materials that can withstand harsh conditions and remain legible over time.

Compliance with Electrical Labeling Standards

Following the correct standards for electrical labeling is not just a matter of safety—it’s a legal requirement. Several key regulations dictate how electrical hazards must be communicated in the workplace, including OSHA standards, NFPA 70E, and NEC guidelines.

OSHA (Occupational Safety and Health Administration)

OSHA requires that electrical panels and other hazardous equipment be labeled to protect worker safety. OSHA’s regulations state that electrical equipment must be clearly marked with warnings, including any danger related to electrical shock or high-voltage exposure.

NFPA 70E (Standard for Electrical Safety in the Workplace)

NFPA 70E provides detailed requirements for labeling electrical hazards, including specific guidelines for arc flash labeling. Arc flash labels must indicate the potential hazard, the appropriate personal protective equipment (PPE), and other vital information needed to protect workers.

NEC (National Electrical Code)

The NEC requires compliant labeling for electrical panels, particularly for equipment operating at high voltages. Labels must provide adequate warning about potential risks to workers and include clear instructions for safe operation.

By complying with these regulations, facilities not only keep their employees safe but also avoid potential fines and legal liability.

Types of Labels for Electrical Panel Safety

Different types of labels are necessary to cover the various hazards associated with electrical panels. These labels help workers understand the specific risks posed by the panel they’re working on.

Warning Labels

Warning labels alert workers to the general dangers of working with electrical panels. Common warnings include “High Voltage,” “Electric Shock Hazard,” or “Do Not Open While Energized.” These labels often use orange for the background and bold text to quickly catch attention.

Text on electrical panel labels must be clear, concise, and easy to read, and a warning label with an orange background and bold text quickly catches attention. Image courtesy of Graphic Products

Arc Flash Labels

Arc flash labels highlight equipment that is capable of releasing dangerous energy during an electrical fault. These labels provide specific details about arc flash boundaries, incident energy levels, and the required PPE to safely work in the area.

A typical arc flash label might read: “Warning: Arc Flash Hazard – PPE Required: Face Shield, Gloves, Protective Clothing. Incident Energy: 8 cal/cm².” This provides workers with all the necessary information to prevent serious injuries during an arc flash incident.

Lockout/Tagout Labels

Lockout/tagout procedures are critical during maintenance to guarantee that electrical panels are completely de-energized before any work is done. Lockout/tagout labels visually indicate that the equipment is not to be operated until maintenance is complete. These labels often include a place for the worker’s name and the date of the lockout.

Instructional Labels

Instructional labels provide guidelines for the safe operation of electrical panels. These labels can include step-by-step instructions for shutting down, isolating, or restarting the panel safely.

Benefits of Correctly Labeled Electrical Panels

Clear and compliant labeling on electrical panels offers numerous benefits, particularly in maintaining safety and compliance.

- Compliance with Regulations: Correct labeling ensures that your facility meets OSHA, NFPA 70E, and NEC standards, avoiding costly fines or legal

- Improved Worker Safety: Proper labeling helps workers identify hazards and take necessary precautions, reducing the risk of electrical accidents.

- Faster Emergency Response: In the event of an emergency, clearly labeled panels make it easier for first responders and facility personnel to quickly assess the situation and take appropriate action.

- Reduced Maintenance Risks: Maintenance teams can perform tasks more efficiently and safely when panels are clearly labeled with lockout/tagout instructions or energy source details.

Print Signs and Labels with an Industrial Sign and Label Printer

Using an industrial sign and label printer in your facility simplifies the creation of custom, durable labels for electrical panels. These printers offer on-demand production of high- quality labels that help ensure compliance with safety standards and minimize risks in electrical work environments.

Built to withstand harsh conditions, they provide a cost-effective, in-house solution for producing clear, long-lasting labels. With features like high-resolution printing, a range of material options, and user-friendly design, these printers are essential for enhancing safety and efficiency in electrical panel management.

Closing the Circuit on Electrical Panel Safety

Electrical panel safety is needed in any workplace, and appropriate labeling is a key component in preventing accidents and maintaining compliance with safety standards. By implementing clear, durable, and compliant labels, facilities can significantly reduce the risk of electrical accidents, improve worker safety, and enhance overall operational efficiency. If your facility has outdated or unclear electrical panel labels, it may be time to evaluate and update them to meet current standards and safeguard your team.

About the Author

Henry Verdine is a safety professional at Graphic Products based in Portland, Oregon. Graphic Products is a global leader in safety labeling and signage for facilities. Read more about visual communications and safety at www.duralabel.com/resources.