Die casting is a casting process used across the industry to create high-precision metal parts from die casting alloys. This article will explore this process to understand how it works, its different types, and the advantages it offers over competing processes.

- The die casting process boasts fast cycle times and high material yield. It is capable of creating some of the most complex designs while maintaining tight tolerances and smooth surface finishes.

- There are two primary types of die casting processes: hot and cold chamber die casting. The first method is faster and more suitable for metals with a lower melting point, the second is slower but can also work with high melting point non-ferrous metals.

- Die casting also has certain limitations such as high initial investment, part size restrictions and greater vulnerability to porosity defects. The process is impractical below a certain volume and above certain part sizes.

What Is Die Casting?

Die casting is a metal casting process that uses metal dies to create metal parts. Molten metal is poured or injected into the metal dies and allowed to solidify. Once solidified, the parts are removed from the mould and put to use after minimal finishing operations.

The die casting process is primarily used for casting non-ferrous metals, such as aluminium, magnesium, zinc and their alloys, but it can also be used for other metals with comparable melting points.

Die casting is essentially the same as injection moulding, as the primary difference lies in the materials used – molten metal vs molten plastic. Additionally, die casting requires higher temperatures and pressures due to the properties of metals, and the moulds are typically made from high-strength steel to withstand these conditions, whereas injection moulding can use moulds made from a variety of materials due to the lower temperatures and pressures involved in processing plastics.

Applications of Die Casting

Die casting is widely used in various industries to produce parts such as:

- Automotive components (engine blocks, transmission cases and wheel rims)

- Consumer electronics (housing for laptops, smartphones and cameras)

- Appliances (handles, brackets and heat sinks)

- Aerospace components (aircraft parts and fittings)

- Industrial equipment (pumps, valve bodies and enclosures)

Die Casting Process

The die casting process can have different mechanics depending on the metal, application and the process employed. For instance, the molten metal could be poured via gravity or injected into the die under high pressure.

Let’s explore a typical die casting process, which involves six main stages:

-

Mould Creation

-

Mould Preparation

-

Metal Injection

-

Cooling

-

Casting Removal

-

Finishing Operations

1. Mould Creation

The mould in die casting is a metal die with an internal cavity the same shape as the product. Nowadays, CAD/CAM and CFD (Computational Fluid Dynamics) software are used to design moulds. These programs can accurately simulate the smallest details about a mould such as internal friction, temperature distribution, flow rates, heat dissipation rate and lubrication efficiency.

After successful simulations, the engineers share the drawings and specifications, such as tolerance and tonnage, with specialist toolmakers. These specialised toolmakers create the mould through CNC machining and run trials to ensure that the final product meets the specifications. In addition to the cavity, an industrial die also contains channels for metal flow, a cooling system and ejector pins.

This is one of the critical stages in die casting. A high-quality mould can eliminate many issues downstream, such as surface defects, material wastage, shrinkage, warpage and incomplete filling.

2. Mould Preparation

The mould preparation stage involves setting up the mold in a way that is most favourable to producing high-quality castings.

The mould is made up of two halves: the fixed die half, which is connected to the injection system, and the removable die half, which separates to remove the casting.

Engineers clean and heat the mould before pouring molten metal into it. They also spray the inner surfaces of the mould with lubricant or refractory material. Of course, these processes can be automated as well.

The lubricant serves multiple functions, including reducing internal friction, aiding in maintaining the die’s temperature, preventing premature solidification of the molten metal in the die, and facilitating the removal of the cast from the die once the metal has solidified.

Finally. the mould halves are closed and secured together using high pressure before pouring the metal.

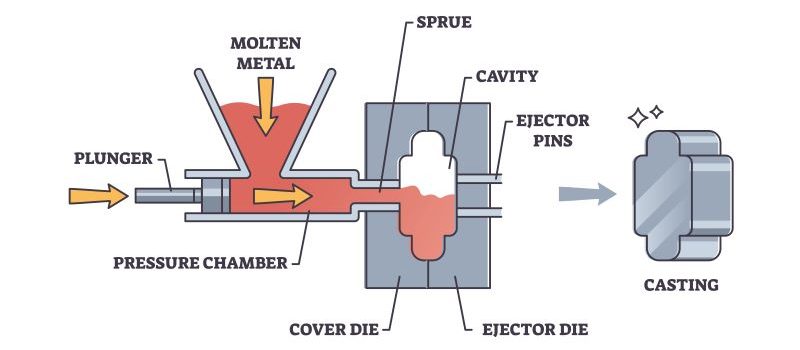

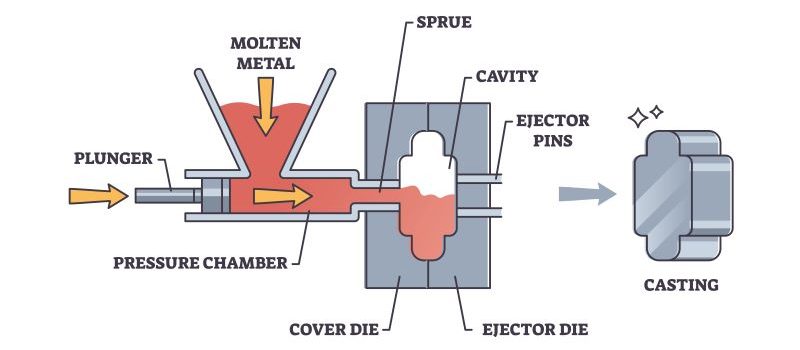

3. Metal Injection

In this stage, molten metal fills the die uniformly. This action can be performed in two ways. One method is gravity die casting, where the force of gravity is utilised to fill all the internal cavities in the mould. This process involves pouring the molten metal from a ladle into a downward sprue that leads to the mould cavity.

The second method, also known as high-pressure die casting, fills the mould by injecting the molten metal into it under high pressure. The pressures can range from 100 bars (1,400 psi) to 1800 bars (26,000 psi). This method offers several advantages over gravity die casting, such as faster and better filling of the mould, the capacity to create intricate structures with thin walls, high dimensional stability, smoother surface finish and the minimisation of finishing operations downstream.

4. Cooling

Once the molten metal has completely filled the mould, the cooling stage begins. It is important to ensure a uniform and controlled cooling rate to obtain the desired microstructure in the final product.

Molten metal must be given enough time to cool to prevent surface or internal defects from forming in the part.

5. Casting Removal

Once the cast is set, the mould halves are unclamped to facilitate the removal of the casting. This may be done manually or automated using ejector pins. The ejector pins are built into the mould to safely and automatically separate the cast when the mould halves are separated.

6. Finishing Operations

Finishing operations are necessary to remove the sprue, runners and other gating system components from the casting. These components are then remelted in the furnace for reuse.

The casting may also need finishing operations, such as surface grinding and machining before it is ready for handover to the customer.

Types of Die Casting

Die casting processes can be carried out under different conditions depending on the specifications of the process and the final part.

Among the many specialist processes in die casting, two are worth elaborating on: the hot chamber die casting and cold chamber die casting processes. Let’s have a look at both of these processes to gain a better understanding.

Hot Chamber Die Casting

The hot chamber in the hot chamber die casting process refers to an internal furnace within the casting machine. The furnace is connected to the die cavity through a feeding system known as the “gooseneck”. As the metal is melted within the casting machine itself, this process offers faster cycle times of about 20 minutes, making it a worthy contender for mass production.

The hot chamber, however, cannot reach very high temperatures. Therefore, the process is most suitable for low melting point metals such as lead alloys, zinc alloys and magnesium alloys. As the metal melts, it is forced into the die through the gooseneck by a plunger.

The plunger withdraws when the metal in the die solidifies. The mould opens and the casting is removed. Then, the mould closes once again, the plunger transfers the hot metal into the die cavity, and repeats the process.

The hot chamber die casting process is popular for its speed, accuracy and consistency. Additionally, it offers a longer die life and improved corrosion resistance.

Cold Chamber Die Casting

The cold chamber die casting process is similar to the hot chamber process, except that the metal is not melted in the casting machine.

The metal is melted in an external high-temperature furnace and transferred to the cold chamber die casting machine via a ladle. In the cold chamber machine, a hydraulic piston forces the metal into the metal die for casting.

This process is suitable for metals with higher melting points such as copper, magnesium, aluminium and their alloys. Magnesium alloys start melting at about 360°C (680°F) and go up to 650°C (1200°F). Therefore, some magnesium alloys can be cast using hot chamber die casting, while others can be cast using cold chamber die casting.

Metals with higher melting points offer greater strength, durability and hardness compared to low melting point metals. Therefore, cold chamber die casting is a better choice for demanding applications.

-

Personal account manager

-

Quality assurance

-

Payment terms for companies

-

On-time delivery by Fractory

Get a quote

Advantages of Die Casting

The die casting process is a modern casting method with numerous unique advantages. Although it has been around for many centuries, it has garnered popularity in recent decades. Let’s explore the advantages of die casting to comprehend why it is a favored choice in the casting industry today:

Complex shapes are a breeze

The die casting industry can create highly complex shapes through this process. It is one of the few processes that can consistently produce high-quality parts at a rapid rate while maintaining narrow tolerances. The high pressures involved are capable of pushing molten metal into the thinnest channels with extreme reliability.

Master at mass production

The quick cycle times, high potential for automation, high material efficiency, and usage of low melting point metals make it highly effective for high-volume manufacturing. The industry uses the process in most serial production applications.

Made for the 21st century

The die casting process can seamlessly incorporate all the latest technology. It is highly compatible with automation and other supporting technologies such as 3D printing and simulation, CAM and CAD software.

First-rate low-cost operation

The cost per piece decreases significantly as the volume increases. Although the initial investment in mould creation and automation integration may be higher than other processes such as sand casting, it more than compensates for it by having one of the lowest operating expenses among all the various types of casting processes.

Buttery smooth finish

Die casting is popular for delivering one of the best surface finishes among casting processes. In many cases, finishing operations may not even be needed, and the product can be put to use after trimming off the excess material from the gating system components.

Additional finishing operations such as grinding, machining and powder coating are only necessary when the application requires a high-quality polish or specific textures.

Limitations of Die Casting

It is equally important to be aware of the limitations and shortcomings of a manufacturing process. Die casting limitations are as follows:

High initial investment

The die casting process involves a significantly higher initial investment compared to other processes. This aspect of die casting can deter interested manufacturers who only have a small number of parts to produce. The economic advantage of die casting lies in mass production. It is not suitable for manufacturing prototypes or small batches of products.

Turbulence can be an issue

The high-pressure injection of molten metal is likely to generate turbulence, which can result in defects like porosity. To address this, most foundries now use flow simulation during mould design. By optimising the mould design and casting process parameters, turbulence can be minimised in the majority of cases.

For example, the metal is initially pushed into the mould with a slow initial velocity to minimise turbulence and the formation of gas bubbles.

Size and weight limitations

Die casting is most suitable for small to medium-sized applications. There are practical limitations on the weight of die-cast parts, as larger castings will naturally require larger dies and related equipment. Process parameters, such as the clamping force and heat dissipation capacity, cannot exceed a certain limit.

As the size of the casting increases, the cost of the process also increases at a greater rate, rendering the process unfeasible beyond the inflection point. In such cases, alternative methods like centrifugal casting may be more appropriate, as they are better suited for larger or cylindrical parts, where uniformity and precision are critical.

To Sum It Up

The die casting process is a modern marvel that can produce the most delicate and complex shapes effortlessly. It surpasses other casting processes, such as sand casting and investment casting, in terms of speed, accuracy, consistency and surface finish. Aluminium die casting, in particular, has been widely utilised in manufacturing to create lighter vehicles while maintaining their original strength.

However, die casting’s disadvantages, such as high initial cost and limitations on size and weight, restrict its use to a small group of applications. Nevertheless, advancements in simulation and automation are enhancing die casting’s capabilities, ultimately expanding its scope within modern manufacturing.