API 570 EXAM STUDY GUIDE

MODULE 9 : PART 2

ASME B31.3 : PROCESS PIPING

Weld joint quality factors and Casting quality factors:

The inspector should be able to determine the weld joint quality factor “Ej” of a longitudinal pipe weld joint. The inspector should be able to determine

-

Casting quality factor, Ec From ASME B31.3, 302.3.3 (b) and Table A-1A

- Weld joint quality factors from ASME B31.3, 302.3.4 and Table A-1B

- Increased joint quality factors by performing supplemental NDE from ASME B31.3 Table 302.3.4

Determine weld joint quality factor may be part of an internal pressure problem since the joint factor Ej is used in the formulas for determining required thickness or internal design pressure.

Here in the weld joint quality factors the student must remember the code clause, 302.3.3 and 302.3.4. The table number also to be remembered i.e., TableA-1A and Table A-1B. In open book exam there will be questions related for the allowable internal pressure or the required minimum thickness of a pipe for a particular situation. At that time the student will have to go to these table’s and clause’s to determine those values. If you remember the clause number it will be easy for you to scroll and pick the values. If you can remember the page number that is even more better than this.

This suggestion is not to confuse you that remembering the page numbers will help to pass the exam but to make you understand that it will save your valuable time during the exam.

Casting quality factor Ec: Clause 302.3.3 and Table A-1A

Clause 302.3.3

Please note that in Ec, for code calculation questions, increased cast quality factor is not mentioned. Please refer point 2, in BOK (Page 2 of 9)

We will go through clause 302.3.3 and Table A-1A.

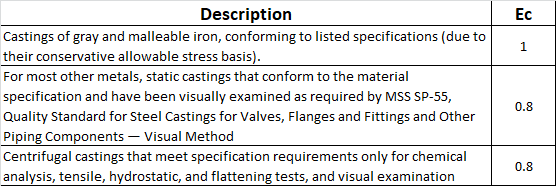

Refer ASME B31.3, Clause 302.3.3 (b); the quality factors are mentioned as follows,

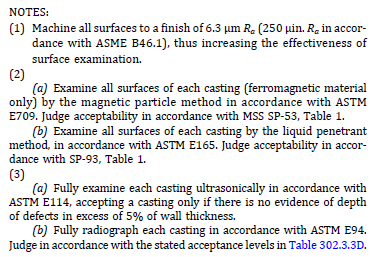

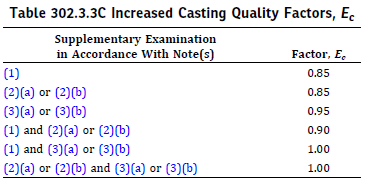

The quality factors can be increased by adding increased NDE. For that refer table 302.3.3C.

First refer the notes given below the table302.3.3C.

[1], [2][a], [2][b], [3][a], [3][b] are additional methods to be performed to increase the quality factor.

The various combinations of additional methods and the quality factor that can be considered by that method are given in the table 302.3.3C

In the above table ‘and’ means both methods are to be performed, ‘or’ means any of the method is to be performed.

Example: [1] and [3][a] or [3][b] means: [1] and [3][a] has to be performed or [1]and [3][b] has to be performed to achieve that quality factor.

The combination of methods other than that mentioned in table 302.3.3C shall not be used to derive a particular quality factor.

In no case shall the quality factor exceed 1.00

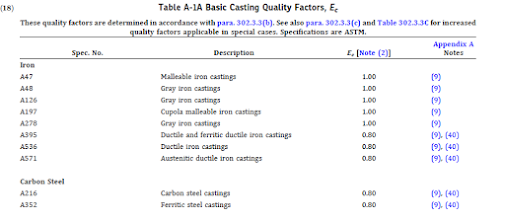

Table A-1A

Ec can be directly taken from Table A-1A for different Specifications and descriptions. By doing additional methods, as mentioned in Table 302.3.3C, the quality factor given in Table A-1A can be increased except those with quality factor 1.00 (Quality factor cannot exceed 1.00).

A snapshot of Table A-1A

Question: What is the casting quality factor for A216 carbon steel castings?

Answer: 0.80; Refer Table A-1A

Question: Based on ASTM E165, liquid penetrant examination is conducted on all the A216 Carbon steel castings. What will be the casting quality factor?

Answer: 0.85; Refer Table 302.3.3C, Supplementary examination of [2][a] or [2][b] will give a quality factor of 0.85

Question: What is the casting quality factor for A47 Malleable iron castings?

Answer: 1.00, Refer Table A-1A

Question: Based on ASTM E165, liquid penetrant examination is conducted on all the A47 Malleable iron castings. What will be the casting quality factor?

Answer: 1.00; casting quality factor cannot be more than 1.00

This blog is not a replacement for the training provided by authorized partners/experienced institutions nor this blog guarantee success in API exams. This blog is the outcome of the approach followed by the author for the preparation of API exams.

Disclaimer: Photos are taken from different websites. If this violates any copyright rules this will be removed. Please inform me if any of the photos or contents violate copyright rules. (through 13hareesh13@gmail.com). This blog is meant for educational purposes only. If it is used for any other means without the written consent from the author, the author will not be responsible. The author does not guarantee the accuracy of the data used in this blog. All the information, data, photo/image, calculations presented in this blog should be used at the sole risk of the user. The blogger is not liable or responsible in any way for any damage, losses or costs arising from the use of the blog for any purpose whatsoever or whosoever it may be. The blog is to be used at your sole risk and responsibility.